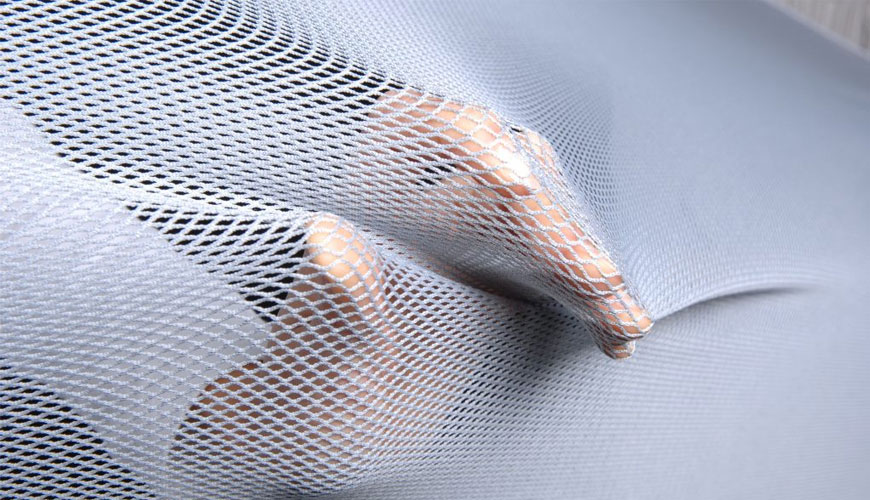

EUROLAB laboratory provides testing and compliance services within the scope of ISO 20932-1 standard. This part of the ISO 20932 standard, developed by the International Organization for Standardization (ISO), describes test methods using straight strips of fabric or loops of fabric that can be used to measure the elasticity and related properties of fabrics, excluding narrow fabrics.

This standard has been developed as a result of technical developments in yarn and fabric structures and properties that increase product diversity and improvements. This standard is based on EN 14704-1.

A fabric test sample of certain sizes is stretched at a fixed rate to a certain force or elongation for an agreed number of cycles, and its elasticity is determined by measuring certain properties.

The metrological verification system of the tensile testing machine shall comply with ISO 10012. The constant elongation rate (CRE) testing machine must comply with the following.

The tensile testing machine should be equipped with means to display or record the force and elongation values when switching between gauge length and a constant load or a fixed extension. Under the conditions of use, the accuracy of the apparatus must be at least 1st class. The error of maximum force displayed or recorded at any point in the range in which the machine is used must not exceed 1% and the error of jaw separation displayed or recorded should not exceed 1 mm.

If the force or elongation recording is obtained through data collection boards and software, the frequency of data collection will be at least eight per second. The machine must have constant elongation rates from 10 mm/min to 20 mm/min with an accuracy of ± 500%. The machine must be able to make variable gauge length settings with an accuracy of ±100 mm, from 250 mm to 1 mm. Clamping or holding devices should be placed so that their center points are in the direction of the applied force. The machine should be calibrated with clamping or holding devices in place and, where appropriate, with the jaw faces closed.

A series of test specimens will be cut from each laboratory specimen in the tensile directions. A set should consist of at least five test samples. No test specimen shall be cut within 150 mm from either side of the laboratory specimen. No longitudinal test specimens should contain the same yarns and no transverse test specimens should contain the same yarns, unless otherwise agreed between the parties concerned.

Among the services provided by our organization within the framework of material testing services, there are also ISO 20932-1 standard tests. Do not hesitate to contact our laboratory EUROLAB for your testing and certification requests.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.