This part of the ISO 294 standard, developed by the International Standards Organization (ISO), specifies a method for determining the molding shrinkage and post-molding shrinkage of injection molded test specimens of thermoplastic material in the direction parallel and normal to the melt flow.

Molding shrinkage, as defined in this document, excludes the effects of moisture uptake. This is included in the shrinkage after molding and therefore the total shrinkage. Inserts are available for cases where shrinkage after molding is due only to moisture removal.

Molding shrinkage as defined in this document represents the so-called free shrinkage with unlimited deformation of the cooling plates in the mold during the holding period. Therefore, it is considered the maximum value of any constrained shrinkage.

In injection molding of thermoplastics, the difference between the dimensions of the mold cavity and the dimensions of the molded products produced from it can vary according to the design and operation of the mold. Such differences may be due to the size of the injection molding machine, the shape and dimensions of the molds including any restrictive effects on shrinkage, the degree and direction of flow or movement of the material in the mold, the dimensions of the material.

Shrinkage after molding and molding is caused by crystallization of the material, volume relaxation and orientation relaxation, and thermal shrinkage of both the thermoplastic material and the mold. Molding and post-molding shrinkage measurement is useful in making comparisons between thermoplastics and checking the uniformity of production.

The method is not intended as a data source for design calculations of components. However, information about the typical behavior of a material can be obtained by making measurements at different melt and mold temperatures, injection rates and holding pressures, as well as at different values of other injection-molding parameters.

The information thus obtained is important in determining the suitability of the molding material for the production of molded products with the correct dimensions.

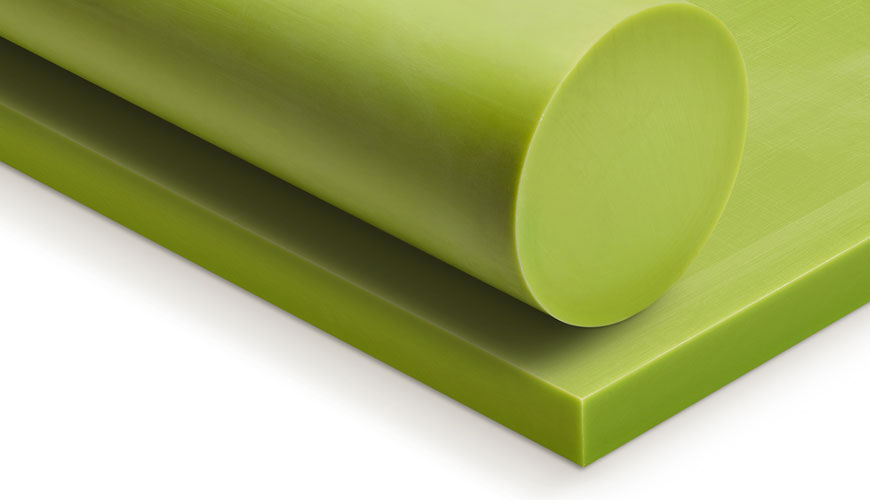

Among the services provided by our organization within the framework of material testing services, there are also ISO 294-4 standard tests. Do not hesitate to contact our laboratory EUROLAB for your testing and certification requests.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.