The ISO 340 standard, developed by the International Organization for Standardization (ISO), specifies a method for assessing the response of a conveyor belt to an igniting flame source on a small scale. It can be applied to conveyor belts with textile carcass as well as steel cord conveyor belts.

Health and safety

Smoke and fumes, ignition and combustion of polymeric materials can produce fumes and toxic gases that can affect the health of operators. It is therefore of paramount importance to provide suitable means for clearing the test area of fumes and fumes.

All relevant local safety regulations shall be taken into account for the transport, storage and disposal of liquefied petroleum gas containers, the transport and storage of liquefied petroleum gas (LPG), and the disposal of used LPG containers.

If local safety regulations require LPG cylinders to be stored in an environment that is cooler than the test area or some distance from the test equipment, sufficient length of tubing is needed within the controlled environment to allow the gas to equilibrate to the required temperature. Before flow measurement. One way to facilitate this is to pass the gas (before flow measurement) through a metal tube immersed in water held at 25 °C.

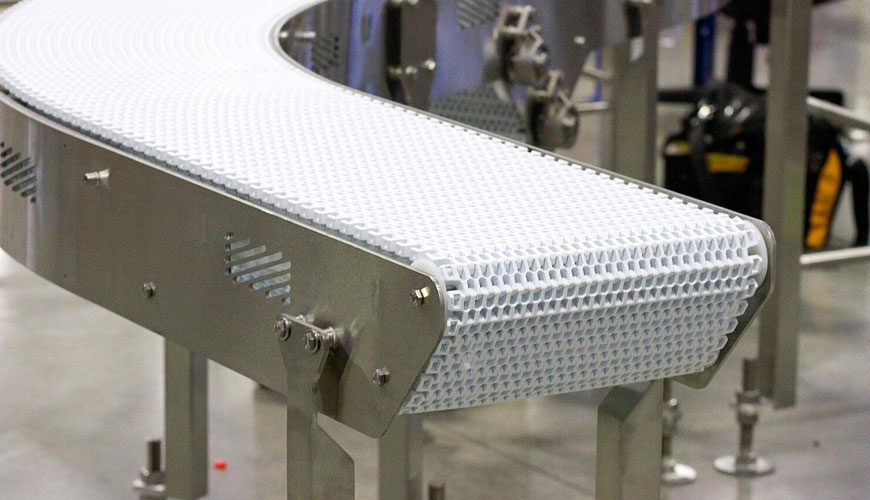

A test piece cut from the conveyor belt is suspended vertically over a gas flame for a specified period of time, after which the gas flame is removed. Burn time is measured. Any reflashing is noted when the test piece is subsequently exposed to a stream of air.

200 test pieces, each (5 mm ± 25 mm) x (1 mm ± 12 mm) are prepared as follows:

Covers can be removed by polishing, cutting. If coatings are removed by polishing, care must be taken not to overheat the test piece or to damage any threads of the textile carcass.

Among the services provided by our organization within the framework of material testing services, there are also ISO 340 standard tests.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.