EUROLAB laboratory provides testing and compliance services within the scope of ISO 6506-1 standard. This part of the ISO 6506 standard, developed by the International Organization for Standardization (ISO), specifies the Brinell hardness test method for metallic materials. It can be applied to both fixed-position and portable hardness testing machines. Certain International Standards exist for some specific materials or products (eg ISO 4498) and refer to this International Standard.

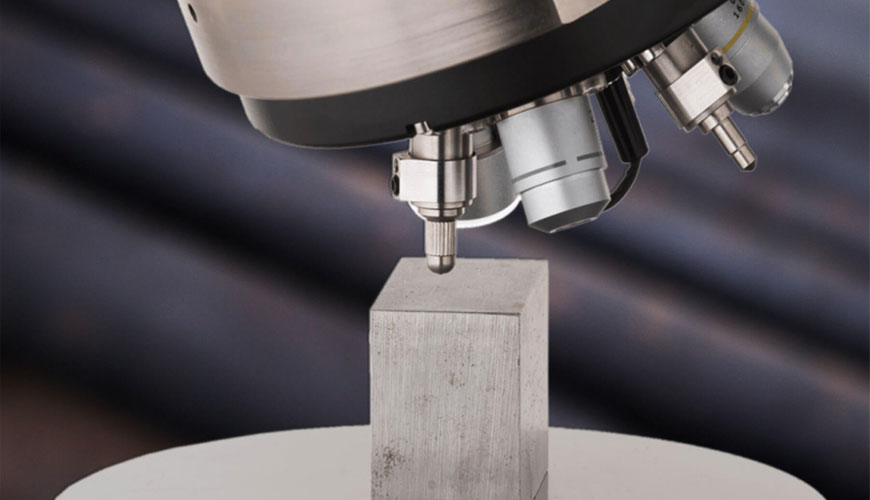

An indentation (diameter tungsten carbide composite ball, D) is forced onto the surface of a test piece, and after the force is removed, F, the diameter of the indentation remaining on the surface, d, is measured.

Brinell hardness is proportional to the quotient obtained by dividing the test force by the curved surface area of the indentation. The recess is assumed to take the shape of the unloaded ball recess tip, and the surface area is calculated from the average recess diameter and ball diameter using the formula.

The test should be performed on a smooth and even surface; free of oxide residue, foreign matter and especially lubricant. The test piece must have a surface finish that will allow the diameter of the recess to be accurately measured. For recesses made with smaller ball recesses, it may be necessary to polish or overlap the surface before recessing.

Preparation should be done in such a way as to minimize any changes to the surface that may occur, for example, due to overheating or cold working. The thickness of the test piece should be at least eight times the depth of the indentation. Values are given for the minimum thickness of the test piece relative to the mean indentation diameter. Visible deformation on the back of the test piece may indicate that the test piece is too thin.

For each scale to be used at the approximate hardness level of the material to be tested, the machine should be checked every day the machine is used.

Among the services provided by our organization within the framework of material testing services, there are also ISO 6506-1 standard tests. Do not hesitate to contact our laboratory EUROLAB for your testing and certification requests.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.