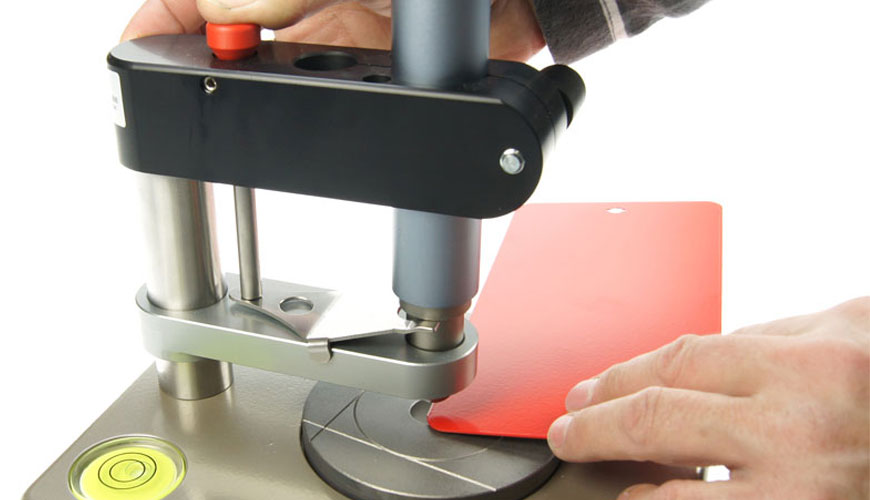

EUROLAB laboratory provides testing and compliance services within the scope of ISO 6603-1 standard. This International standard specifies methods for determining the puncture-impact properties of rigid plastics.

Samples can be directly molded, cut from sheets or taken from finished products. Different test samples and test types conditions are defined. These falling dart methods are used to investigate the behavior of plastic sheeting or molds under impact.

This part of ISO 6603 may be used if it is sufficient to characterize the impact behavior of plastics with a threshold value. ISO 6603-2 is used if there is a force-deviation or force-time.

These test methods are applicable to specimens with a thickness of between 1 mm and 4 mm. For thicknesses less than 1 mm, preferably ISO 7765 should be used. Thicknesses greater than 4 mm may be the suitability of the equipment has been tested, but testing is outside the scope of ISO 6603-1 and ISO 6603-2.

These methods are suitable for use with the following material types:

The test results, however, are the same as the preparation conditions, dimensions and surfaces of the samples and test conditions. In particular, the results determined on different samples thickness cannot be compared with each other. Comprehensive assessment of response to impact stress requires determinations to be made as a function of impact velocity and temperature.

The impact behavior of finished products cannot be predicted directly from this test, but samples can be taken. Test data developed by these methods should not be used for design calculations.

The typical behavior of the material can be obtained by testing at different temperatures and impact velocities, by varying the thickness and testing the samples were prepared under different conditions.

Two statistical testing methods are described in this part of ISO 6603:

Method A ladder method (individual) preferred: This method uses a uniform energy boost during testing.

Method B: In this method, consecutive groups of at least ten test samples are tested. Impact failure energy is calculated by statistics.

EUROLAB assists manufacturers with ISO 6603-1 test compliance. Our test experts, with their professional working mission and principles, provide you, our manufacturers and suppliers, the best service and controlled testing process in our laboratories. Thanks to these services, businesses receive more effective, high-performance and quality testing services and provide safe, fast and uninterrupted service to their customers.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.