EUROLAB laboratory provides testing and compliance services within the scope of ISO 75-1 standard. The ISO 75-1 standard, developed by the International Standards Organization (ISO), gives a general test method for determining the deflection temperature of plastics under load (bending stress under three-point loading). Different test specimen types and different constant loads are defined to suit different material types.

The specified method is suitable for evaluating the relative behavior of different types of materials at high temperature under load at a given temperature rise rate. In practice, the results obtained may not be representative of the maximum applicable temperatures, as key factors such as time, loading conditions and nominal surface tension may differ from the test conditions. True comparability of data can only be obtained for materials with the same room temperature flexural modulus.

The ISO 75-1 method specifies the preferred dimensions for test specimens. Data obtained using the test method described is not used to estimate actual end-use performance. The data are not intended for design analysis or estimation of the durability of materials at elevated temperatures.

This method is commonly known as heat deflection temperature or heat distortion temperature (HDT) testing, although there is no official document using this nomenclature.

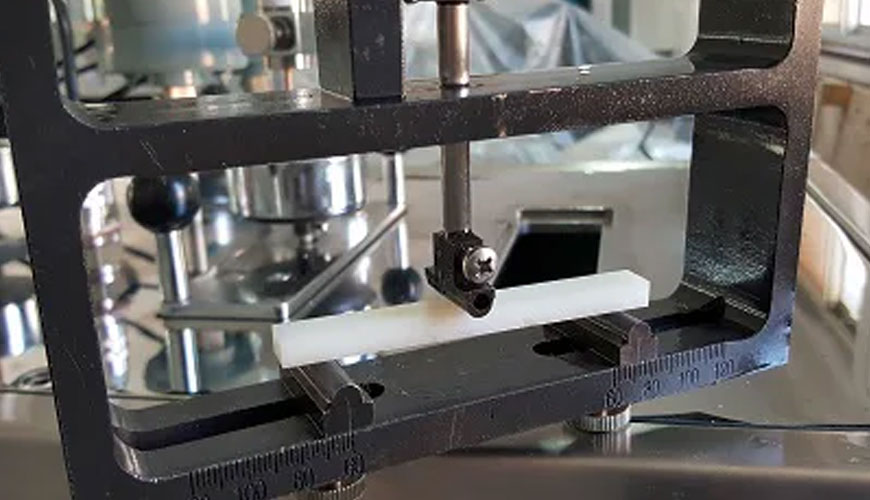

A standard test specimen is subjected to three-point bending under a constant load in the straight (preferred) or edge position to produce one of the bending stresses given in the relevant section of this International Standard. The temperature is raised at a uniform rate and the temperature at which the standard deviation corresponding to the specified increase in bending strain occurs is measured.

Test specimen supports consist of metal parts that are cylindrical in the contact area and at the lines of contact with the specimen in a horizontal plane. The size of the opening, ie the distance between the lines of contact, is given in the relevant part of this International Standard. The supports are attached to the base of the frame so that the vertical force exerted on the test specimen by the loading edge is in the middle of them. The contact edges of the supports are parallel to the loading edge and at right angles to the length direction of the test specimen placed symmetrically on them. The contact edges of the supports and the loading edge must have a radius of (3,0 ± 0,2) mm and be longer than the width of the test specimen.

Unless the vertical portions of the apparatus have the same coefficient of linear thermal expansion, the difference in length variation of these parts will cause an error in reading the apparent deflection of the test specimen. A blank test should be performed on each apparatus using a test specimen made of rigid material with a low coefficient of expansion and a thickness comparable to that of the specimen under test.

The blind test should cover the temperature ranges to be used in the actual determination and a correction term should be determined for each temperature. If the correction term is 0,01 mm or greater, its value and algebraic sign should be recorded and the term applied to each test result by adding the term algebraically to the reading of the apparent deviation of the test sample.

The heating equipment should be a heating bath containing a suitable liquid in which the test specimen can be immersed to a depth of at least 50 mm. An efficient mixer will be provided. It should be determined that the selected liquid is stable in the temperature range used and does not affect the material under test, causing the sample to swell or crack.

Among the services provided by our organization within the framework of material testing services, there are also ISO 75-1 standard tests. Do not hesitate to contact our laboratory EUROLAB for your testing and certification requests.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.