EUROLAB, with its state-of-the-art accredited laboratories and expert team, provides precise and fast testing services within the scope of ISO 7854 testing. This standard describes three methods for assessing the resistance of coated fabrics to damage by repeated stretching.

Investigation of the dynamic-flexible fatigue properties of coated fabrics has suffered from poor repeatability (partly due to the unknown but unavoidable variability of the tested material) and worse repeatability for several years. However, the dynamic-flexible performance of coated fabrics has long been widely used as a measure of product quality.

Traditionally used methods suffered from the widespread lack of testing only a small test piece. The De Mattia test is not suitable for materials that exhibit "setting" such as thermoplastics and the Schildknecht method has disadvantages when testing heavier industrial fabrics and also tends to require very high geometric ratios and thus time consuming testing to validate results. In addition, the assembly of Schildknecht test pieces can severely affect test results and repeatability.

Both the De Mattia and Schildknecht methods are also one-sided; this is advantageous in some situations, but not suitable in most cases, for example where bidirectional voltages are applied during use.

This revised edition of ISO 7854 attempts to standardize the assembly difficulties associated with the Schildknecht apparatus (method B) and presents a two-way flex fatigue test that provides a large test piece, enabling post-flexible examinations such as hydrostatic head tests. will be executed. The device is described in ISO 8096-3:1988, Rubber or plastic coated fabrics for water resistant clothing - Specification - Part 3: Natural rubber and synthetic rubber coated fabrics. The apparatus outlined there descriptively has been developed in more detail and is now widely available commercially from a number of sources.

The stretch test can be a useful indicator of the durability of coated fabrics. However, for most applications, the flexing conditions caused by these test methods are different from the conditions met in practice. In particular, the induced microclimate around the test piece and the thermal stresses induced in the molecular structure of the coating during flexing are unlikely to represent practical situations.

Therefore, it is important to keep these effects to a minimum and to consider their effects when evaluating test results. Consequently, it is important to ensure that the air temperature around the test pieces is kept constant during testing. This is either open ventilation around the test pieces, without sufficient forcing, or controlling the air temperature in any closed vessel in which the test apparatus may be mounted.

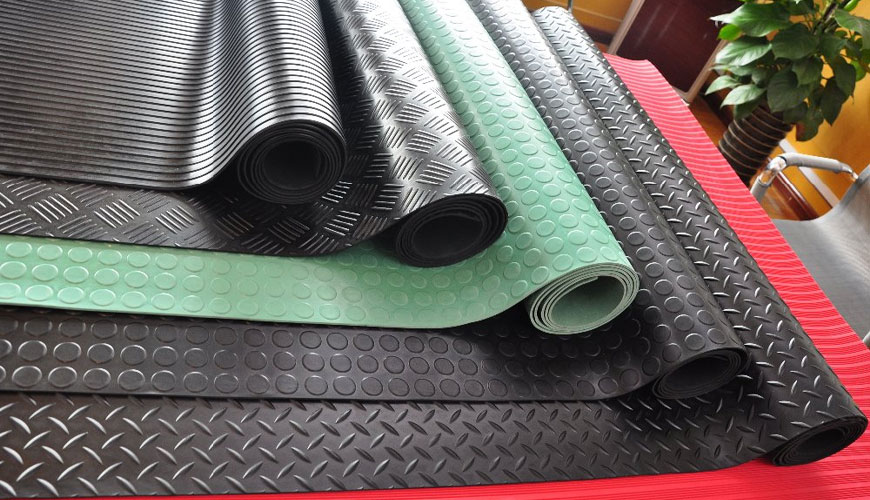

Three methods are described. Method A (De Mattia) may be found suitable for fabrics with flexible test coatings that cannot be constrained by the configuration required by method В or where the amount of material available for testing is too small to allow other methods to be used. Method В (Schildknecht) will be found useful for the stretch testing of coated fabrics that have a relatively light structure or are in the light to medium range in terms of flex strength for practical use.

Method С (crease/stretch test) has been found useful in testing coated fabrics that will be subjected to serious use for their ability to stretch under harsh conditions. The method requires a large test piece, but this provides certain advantages for selecting test pieces for relevant tests after flexing, eg hydrostatic head testing.

Some coated fabrics are more susceptible to delamination when they are spun in the wet condition and attention is drawn to the information in Appendix A .

Due to the differences in the nature of stretching in the three methods, a true correlation of results between the different methods is not possible.

EUROLAB assists manufacturers with ISO 7854 test compliance. Our test experts, with their professional working mission and principles, provide you, our manufacturers and suppliers, the best service and controlled testing process in our laboratories. Thanks to these services, businesses receive more effective, high-performance and quality testing services and provide safe, fast and uninterrupted service to their customers.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.