EUROLAB laboratory provides testing and compliance services within the scope of ISO 9932 standard. The ISO 9932 standard, developed by the International Standards Organization (ISO), describes the general test methods for determining the water vapor transmission rate of sheet materials by means of the dynamic gas method or the static gas method.

Depending on the method used and the specific apparatus, materials up to 38 mm thick and with water vapor transmission rates in the range of 0,05 g/(m²·d) to 65 g/(m²·d) can be tested. The basis of the function of instrumental techniques is briefly explained.

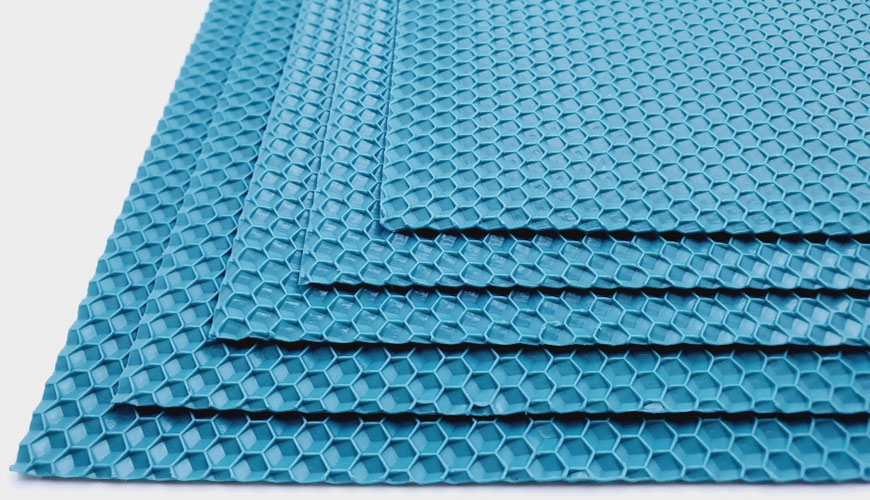

The rate of water vapor penetration through a barrier is an important property in many applications such as building and packaging. ISO 2528 describes a dish method for determining the transmission rate and this method is widely accepted. However, it has three disadvantages. Results take several days to obtain, are not suitable for transfer rates below 1 g/(m2·d) and are not recommended for materials thicker than 3 mm.

The methods described in this document can produce results within a few hours, depending on the material tested, and are suitable for materials with transmission rates considerably less than 1 g/(m²·d). Depending on the special tool, they are also suitable for materials up to 38 mm thick.

The test piece is mounted between two chambers. One was swept at a known relative humidity and the other with a dry gas. The amount of water vapor picked up by the dry gas stream is converted into a reading by an electrical sensor and, directly or after calculation, a measure of the rate of water vapor transmission through the test piece.

The test piece is mounted in a cell containing an electrolytic element and the cell is placed in a humidity cabinet at the required temperature and relative humidity. The water vapor entering the cell is electrolyzed and as a result the relative humidity inside the cell remains very low (< 1%). After equilibrium, the electric current is a direct measure of the rate of electrolysis (according to Faraday's law of electrolysis) and the rate of water vapor transmission.

Among the services provided by our organization within the framework of material testing services, there are also ISO 9932 standard tests. Do not hesitate to contact our laboratory EUROLAB for your testing and certification requests.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.