DIN 53459 Testing of Plastics - Evaluation of Behavior During and After Contact with a Glow Rod

EUROLAB, with its state-of-the-art accredited laboratories and expert team, offers precise and rapid testing services within the scope of DIN 53459 testing. Plastic materials are designed and manufactured in a wide range for use in various industries. Various tests are performed to evaluate the performance of these materials.

Physical and Mechanical Tests:

- Tensile Test: It is used to determine the tensile strength, modulus of elasticity and elongation at break of the plastic.

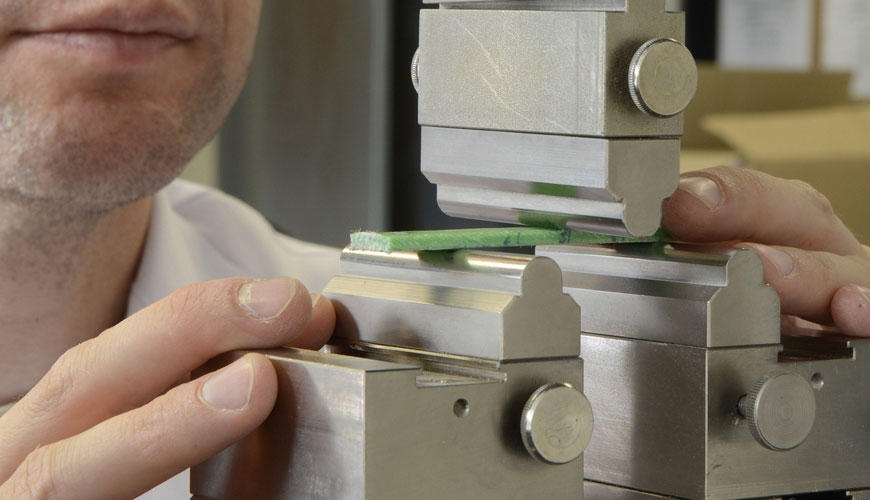

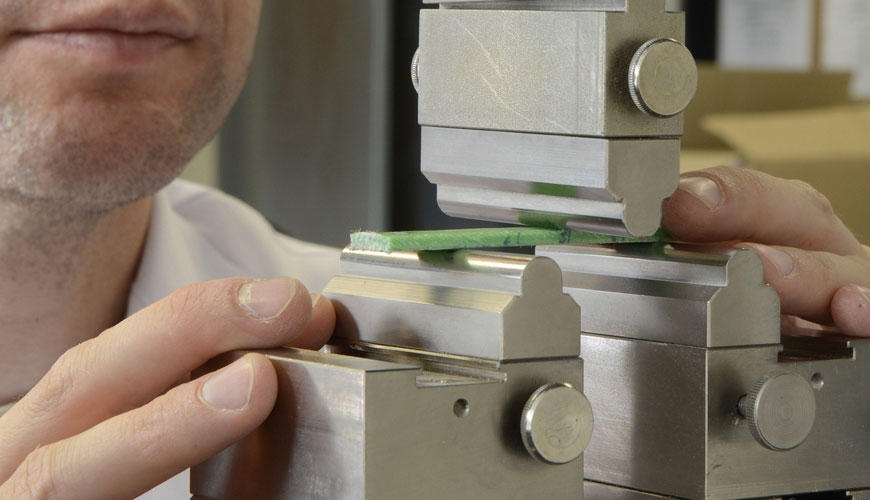

- Flexural Test: Measures the bending strength and modulus of elasticity of plastic.

- Shock Resistance: Various impact tests are performed to determine the impact resistance of the plastic material.

Thermal Tests:

- Melting Point: Thermal analysis methods are used to determine the melting point of plastic.

- Heat Exchange Capacity: Thermal analyzes are performed to measure the heat storage capacity of plastic.

Chemical Resistance Tests:

- Chemical Resistance Tests: It is performed to determine the resistance of the plastic material to various chemicals.

- Wear Resistance: Tests are performed to evaluate the resistance of the plastic material to abrasion and scratching.

Electrical Tests:

- Dielectric Strength: Dielectric strength tests are performed to determine the insulation properties of the plastic material.

- Surface Resistance: These are tests that measure the electrical resistance of the plastic surface.

Ultraviolet (UV) Resistance Tests:

- UV Aging Test: It is performed to evaluate how the plastic material changes during exposure to UV rays.

Visual Evaluation:

- Color Stability: Color stability tests are performed to evaluate the color durability of the plastic material.

- Surface Quality: Visual tests are performed to evaluate the smoothness, gloss and other visual characteristics of the plastic surface.

These tests are used in the design processes, quality control and durability analysis of plastic materials. Industry standards and specific test methods for specific applications are used in these tests.

EUROLAB assists manufacturers with DIN 53459 test compliance. Our test experts, with their professional working mission and principles, provide you, our manufacturers and suppliers, the best service and controlled testing process in our laboratories. Thanks to these services, businesses receive more effective, high-performance and quality testing services and provide safe, fast and uninterrupted service to their customers.