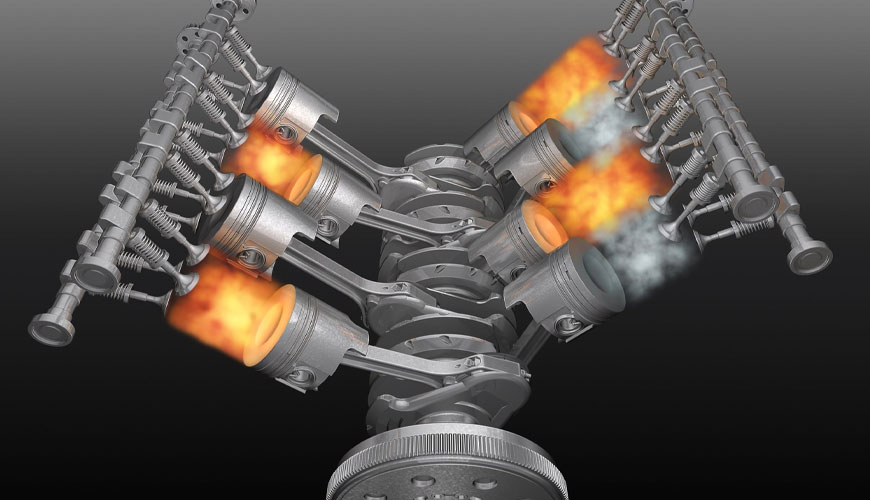

EUROLAB, with its state-of-the-art accredited laboratories and expert team, provides precise and fast testing services within the scope of EN ISO 6621-4 testing. EN ISO 6621-4 specifies the general characteristics of piston rings for reciprocating internal combustion engines for road vehicles and other applications (separate size criteria for these rings are given in the relevant International standards). It also provides a system for ring coding, assignment and marking. Applicable to all rings with nominal diameter from 30mm to 200mm (inclusive).

The requirements and recommendations for piston ring marking apply to piston rings with a radial wall thickness of 1,6 mm and above. Marking of piston rings smaller than 1,6 mm is at the discretion of the manufacturer. All rings requiring orientation shall be marked to show only the top (ie, the side closest to the combustion chamber).

The marking of the upper side applies to all the following ring types:

For surface-treated piston rings, light tightness is normally measured prior to surface treatment. When checked after the operation, the ring on the indicator will need to be rotated. In negative point deflection rings, visible light is allowed at the butt ends, but must be limited to the angle θ as defined in EN ISO 6621-2.

Piston rings must be reliably protected against corrosion for a period of at least one year in normal dry storage. The type and properties of the protector will be agreed between the manufacturer and the customer, taking into account the storage life, storage conditions, assembly requirements and all relevant legal regulations.

A piston ring manufacturer's quality and production data can be agreed upon batch coding with an appropriate identification code for each ring so that the piston rings can be accessed at any time after delivery before the first engine start-up. Traceability down to the single ring level is not intended. The scope of data to be documented and coding methods will be agreed between the customer and the manufacturer.

EUROLAB assists manufacturers with EN ISO 6621-4 test compliance. Our test experts, with their professional working mission and principles, provide you, our manufacturers and suppliers, the best service and controlled testing process in our laboratories. Thanks to these services, businesses receive more effective, high-performance and quality testing services and provide safe, fast and uninterrupted service to their customers.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.