Developed by the American Society for Testing and Materials (ASTM), the ASTM A36 standard includes structural steel shapes, plates and bars for use in riveted, bolted or welded construction of bridges and buildings and for general structural purposes. This standard provides a heat analysis method to determine the required chemical composition for carbon, manganese, phosphorus, sulfur, silicon and copper. Tensile strength, yield strength and elongation properties are evaluated using the tensile test. In this regard, the material must comply with the required tensile properties. The full name of the standard in question is: ASTM A36 /A36M-19 standard specification for carbon structural steel.

Additional requirements are provided in the ASTM A36 standard for use where other testing or additional restrictions are required by the purchaser. Such requirements apply if specified in the purchase order.

Also, if steel welding is required during the use of the material, a welding procedure appropriate to the steel grade and the intended use or service should be used. Requirements for weldability are contained in the annex (Annex X6) of the ASTM A6/A3M standard.

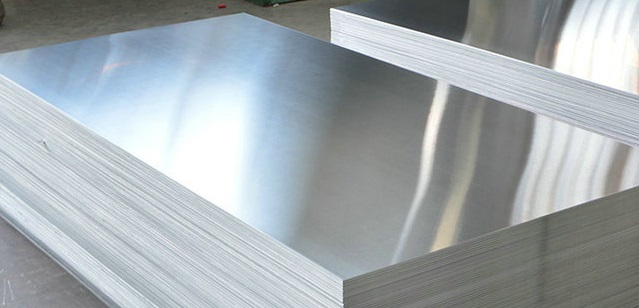

A36 steel is a commonly used structural steel in the USA. Like many steels, A36 steel has a density of 7.800 kg/m3. A36 steel is in the form of sheets and bars less than about 20 cm thick and has a minimum yield strength of 36 psi and an ultimate tensile strength of 58 to 80 psi. Plates thicker than 20 cm have a yield strength of 32 thousand psi and the same ultimate tensile strength. The electrical resistance of A36 steel is 20 μΩm at 0.142 degrees. A36 bar steels retain their ultimate strength up to 343 degrees.

Steels conforming to the ASTM A36 standard are easily welded by all welding processes. Briefly, the most common welding methods for this steel are the cheapest and easiest, such as shielded metal arc welding, gas metal arc welding, or oxyacetylene welding. A36 steel is also commonly bolted and riveted in structural applications.

After all, steel conforming to the ASTM A36 standard is the most commonly used mild and hot rolled steel. It has excellent welding properties and is suitable for grinding, drilling, tapping and machining processes. Generally, A36 steel is available in the following shapes: rectangular bar, square bar, circular bar and steel shapes such as channels, angles, H beams and I beams.

ASTM A36 steel has a machinability of 72 percent and an average surface cutting feed of 120 ft/min. However, the processing of this steel is not as easy as AISI 1018 steel. This steel is easy to weld by any welding method and the welds and joints thus formed are of excellent quality.

In general, ASTM A36 steel has the following applications:

Steel is one of the most common metals used for structural applications. It has strong, tough, ductile, formable and weldable properties. It is important to know the basic properties of A36 steel for on-site use, as there are many different types of steel available, each with unique chemical and mechanical properties.

A36 steel is a low carbon steel. It has less than 0,3 percent carbon by weight. Therefore, A36 steel can be easily machined, welded and formed, and A36 steel is extremely useful as a general purpose steel. Due to its low carbon content, heat treatments are not very effective on this steel. It usually contains small amounts of other alloying elements such as manganese, sulfur, phosphorus and silicon. These elements are added to A36 steel to impart the desired chemical and mechanical properties. A36 steel does not contain large amounts of nickel or chromium and therefore has low corrosion resistance.

Our organization provides standard specification services for carbon structural steel within the scope of ASTM A36 standard, within the framework of national and international standards, with its trained and expert staff and advanced technological equipment, among numerous test, measurement, analysis and evaluation studies.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.