EUROLAB, with its state-of-the-art accredited laboratories and expert team, provides precise and fast testing services within the scope of ISO 9591 testing. ISO 9591 specifies a method for determining the resistance of aluminum alloys to stress corrosion cracking (SCC).

It covers the sampling method, sample types, loading procedure, environment type, and interpretation of results.

This International standard aims to determine the resistance to SCC as a function of the chemical composition, production method and heat treatment of aluminum alloys.

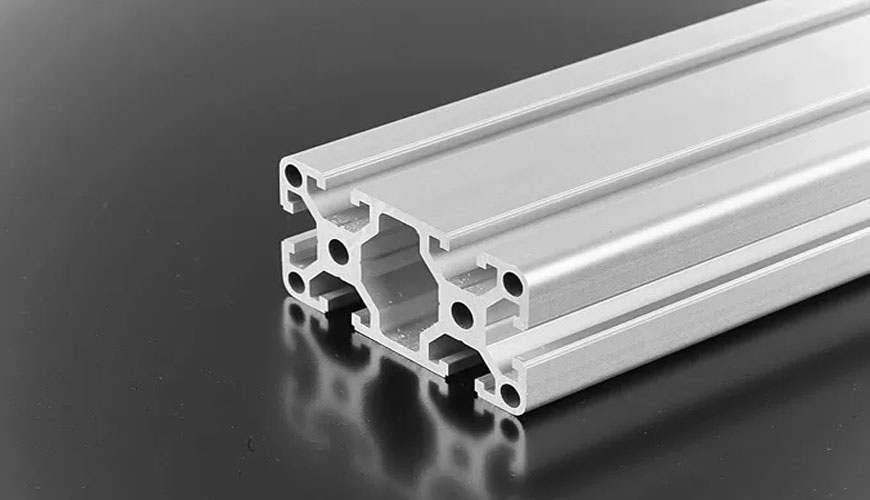

It applies to cast and machined aluminum alloys in the form of castings, semi-finished products, parts and welded joints.

Since most natural and many artificial media contain chlorides, ISO 9591 can be used to compare the performance of products used under marine atmospheres and in chloride-containing environments, provided the failure mechanism is unchanged.

It does not cover slow strain rate test methods and determination of the maximum acceptable stress by permanent deformation method for aluminum alloys, but efforts are being made to apply such methods to these alloys.

The choice of loading method, value of stresses, corrosive environment and evaluation criteria may be the subject of agreement between the parties involved and should be defined by the test program.

Sample holders should be designed to electrically isolate samples from each other and from any bare metal parts. Where this is not possible, as with certain tension bolts or gauges, bare metal in contact with the sample should be isolated from the abrasive with a suitable coating.

Protective coatings shall be of a type that will not leak inhibitory or accelerating ions or protective oils or leave any residue, e.g. Steam in the uncoated parts of the sample. In particular, coatings containing chromate should be avoided. It is recommended to degrease all samples after coating.

EUROLAB assists manufacturers with ISO 9591 test compliance. Our test experts, with their professional working mission and principles, provide you, our manufacturers and suppliers, the best service and controlled testing process in our laboratories. Thanks to these services, businesses receive more effective, high-performance and quality testing services and provide safe, fast and uninterrupted service to their customers.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.