EUROLAB laboratory provides testing and compliance services within the scope of DIN 51819-2 standard. The method is used for mechanical-dynamic testing of lubricating greases, angular contact ball bearing or tapered roller bearing with roller bearing tester FE8.

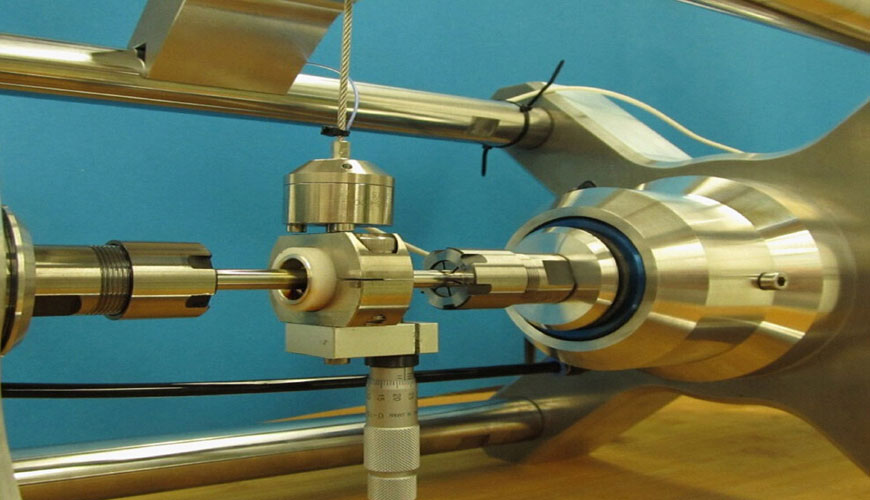

Two angular contact ball bearings or tapered roller bearings are mounted as test bearings in the rolling bearing lubricant tester FE51819 according to DIN 1-8, loaded by the respective axially oriented test force Fa, run at the corresponding test speed n, and any steady state temperature between RT and 200°C with the aid of heater Ub. The steady state temperature should be a multiple of 10°C.

The temperature sensor and friction torque cable should be checked for mobility. The force transducer will be calibrated with three force levels before the test run begins.

After start-up, external heating is turned on in the controller and, if necessary, adjusted until the desired steady-state temperature is reached. Thermocouples should be checked for ease of movement. Temperature control will be performed with temperature sensors and downstream data acquisition system.

EUROLAB assists manufacturers with DIN 51819-2 test compliance. Our test experts, with their professional working mission and principles, provide you, our manufacturers and suppliers, the best service and controlled testing process in our laboratories. Thanks to these services, businesses receive more effective, high-performance and quality testing services and provide safe, fast and uninterrupted service to their customers.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.