EUROLAB, together with its state-of-the-art accredited laboratories and expert team, provides precise and fast testing services within the scope of DIN 51453 testing. This standard covers an infrared spectrometric method for the determination of oxidation and nitration of used motor oils.

DIN 51453 is another German Industrial Standard that deals with the testing of lubricants, with a particular focus on the determination of oxidation and nitration in used engine oils using the infrared spectrometric method. This standard provides guidelines and procedures for assessing the extent of oxidation and nitration, two major degradation processes that occur in motor oils during their service life.

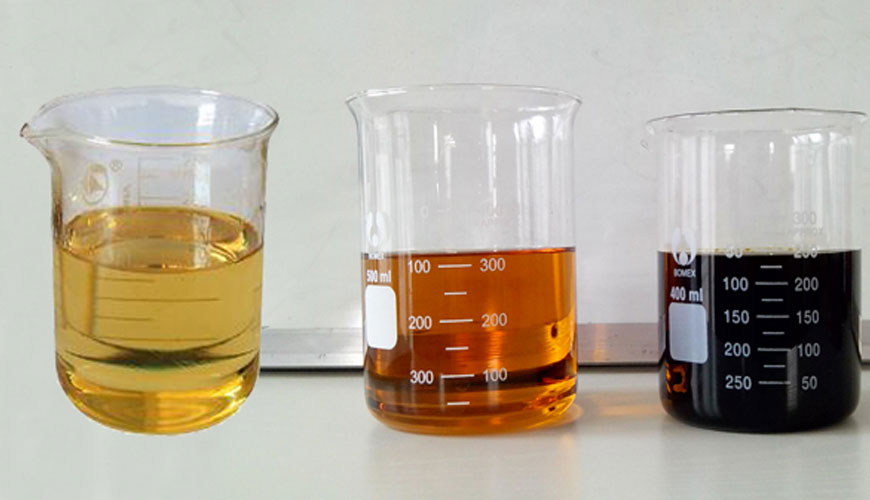

Oxidation is the reaction of engine oil with oxygen and leads to the formation of various oxidation products such as acids, sludge and varnish. On the other hand, nitration results in the formation of nitration by-products, where nitrogen oxides react with the oil. Both oxidation and nitration can adversely affect the performance and protective properties of engine oil.

The test method described in DIN 51453 typically includes the following steps:

DIN 51453 assesses the extent of oxidation and nitration in used engine oils, helping to assess the condition of the oil and its suitability for further use in engines. Regular monitoring of these degradation processes is important in determining optimum oil change intervals and ensuring that the engine oil provides adequate protection to engine components throughout its service life.

EUROLAB assists manufacturers with DIN 51453 test compliance. Our test experts, with their professional working mission and principles, provide you, our manufacturers and suppliers, the best service and controlled testing process in our laboratories. Thanks to these services, businesses receive more effective, high-performance and quality testing services and provide safe, fast and uninterrupted service to their customers.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.