EUROLAB, with its state-of-the-art accredited laboratories and expert team, provides precise and fast testing services within the scope of DIN 52347 testing. The abrasion test according to the friction wheel method of this standard is used to test the sliding wear behavior of glass and clear plastic, preferably safety glass materials for motor vehicles. The test is performed on flat surfaces. The increase in scattered light acts as the measurement variable.

Abrasion testing is very important for evaluating the durability and wear resistance of materials, especially those subject to friction and mechanical wear over time. In the context of glass and plastics, such tests relate to a variety of applications, including vehicle lenses, eyeglass lenses and other transparent or translucent components.

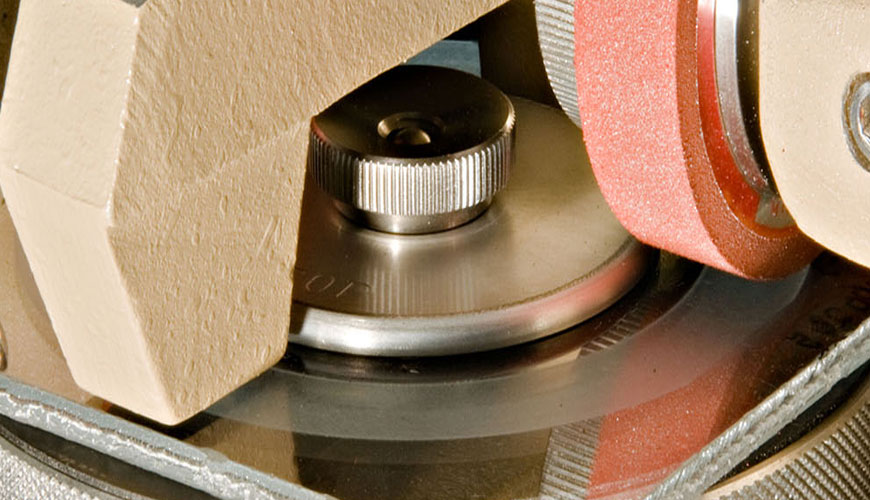

The specimen on the turntable of the wear tester is subjected to sliding wear by two friction wheels rotating in opposite directions. The increase in scattering of transmitted light due to surface changes during the wear test serves as a measure of wear.

The standard likely outlines how to analyze scattered light measurement data and how to interpret the results to evaluate the abrasion resistance of the material. This may include comparing results against established criteria or standards.

By following the procedures described in DIN 52347, manufacturers and researchers can evaluate the wear resistance of glass and plastic materials and make informed decisions about their suitability for specific applications. This helps ensure that materials can withstand wear and retain their function, clarity and appearance over time.

EUROLAB assists manufacturers with DIN 52347 test compliance. Our test experts, with their professional working mission and principles, provide you, our manufacturers and suppliers, the best service and controlled testing process in our laboratories. Thanks to these services, businesses receive more effective, high-performance and quality testing services and provide safe, fast and uninterrupted service to their customers.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.