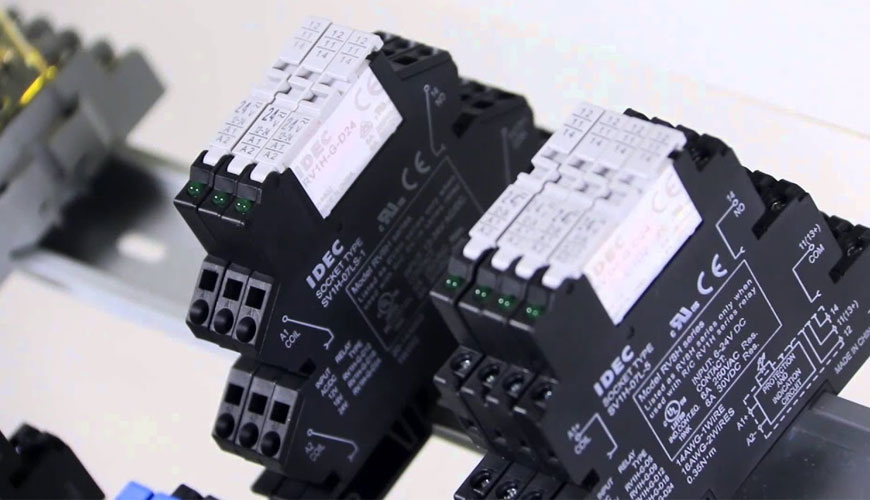

EUROLAB laboratory provides testing and compliance services within the scope of EN 61810-1 standard. This part of the EN 61810 standard applies to electromechanical basic relays (all or nothing relays with unspecified time) for inclusion in low voltage equipment (circuits up to 1000 V alternating current or 1500 V direct current).

Such as general industrial equipment, electrical utilities, electrical machinery, electrical appliances for home and similar use, building automation equipment, automation equipment, electrical installation equipment, medical equipment, control equipment, telecommunications, vehicles, transportation (e.g. railways), information technology and business equipment It defines basic functional and safety requirements and safety considerations for applications in all areas of electrical engineering or electronics.

Compliance with the requirements of this standard is verified by the specified type tests. If a relay application specifies additional requirements that exceed those specified in this standard, the relay should be evaluated against that application according to the relevant IEC standard(s).

This fourth edition cancels and replaces the third edition published in 2008. This edition is a technical revision. This edition contains important technical changes compared to the previous edition.

In the standard, it is emphasized that the test of the relay for heating is carried out on the reinforced coil(s) of the relay and loaded with the current of all contacts. In practice this requirement is impossible to fulfill because if the relay has both normally open and normally closed contacts, it is not possible to charge a current to both contacts at the same time.

In this standard, the dielectric strength procedure is presented. Therefore, it is recommended to apply a variable sine wave voltage with a frequency of 50 or 60 Hz or a selected DC voltage as the one minute test voltage. The voltage values presented in them are absolutely the same for the same type of connections in the circuit diagram. But actually, it refers to the rms values of AC voltage and other DC voltages in a table. As is known, 1000 V rms voltage affects insulation quite differently from 1000 VDC. In terms of the effect on the insulation, even in the simplest case it is necessary to inject at least a factor of 1, even if the known physical effects associated with the effect of the frequency of an alternating voltage on the insulation are neglected.

EUROLAB, with its more than 25 years of experience, state-of-the-art accredited laboratories and expert team, helps you get precise and fast results. Do not hesitate to contact our laboratory for your testing and certification requests.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.