An X-ray inspection system makes it possible to easily detect contaminants in products. The following pollutants are detected with X-ray technology:

X-ray devices are used for various quality controls as well as contaminant detection. Namely,

The benefit of the X-ray inspection system is that it provides a view of the internal composition of solid materials that is invisible to the naked eye. These tests reveal hidden flaws or inconsistencies in the materials used to create the product. These inconsistencies arise in new designs, material changes, or new manufacturing processes. Finding inconsistencies is important because they affect the performance of the product. The consequences of poorly made products result in shorter life cycles, poor performance rates, and failure to meet industry standard and quality requirements.

X-ray inspection determines the suitability and reliability of the product for service. The benefits of X-ray testing during inspection provide details of the manufacturing process according to product construction specifications. Displaying product properties or attributes, such as internal shrinkage, cracks or weaknesses, internal integrity composition, welding or brazing attributes, and wear status, constitutes approval or disapproval based on findings.

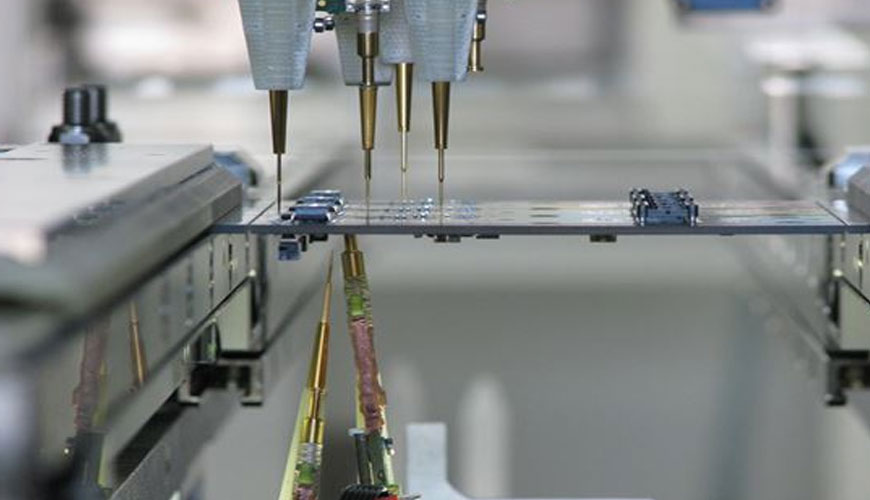

Every industry applies various tests as part of production and quality control. The development of smaller components that integrate into higher-performance processes increases the need for radiographic testing. The benefits of this test are twofold. Customers get consistent reliability that increases lifespan, while the manufacturer produces higher quality products that require less rework. Capturing a high-resolution image of the internal structure and weld with X-ray inspection facilitates reliability through detection of cracks and coating defects, stress measurements and material testing.

Our organization has a strong staff that closely follows the developments in the world in the field of science and technology and constantly improves itself. X-ray inspection services are among the numerous test, measurement, analysis and evaluation studies given to businesses.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.