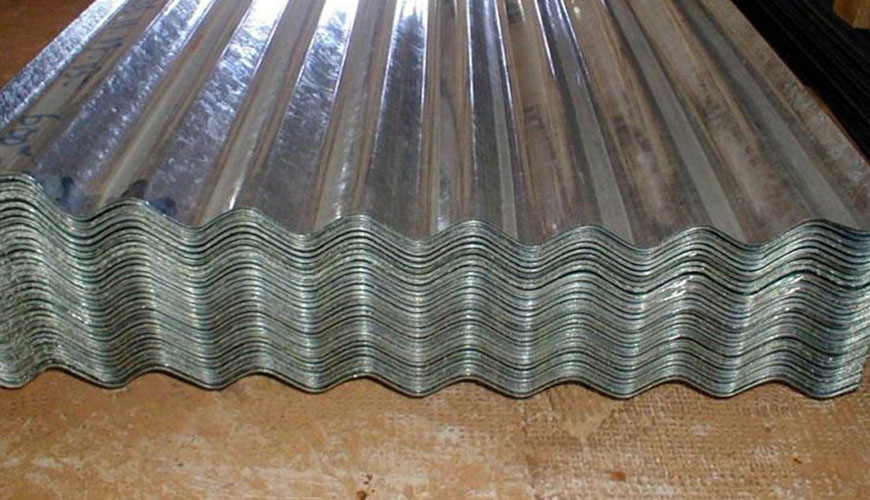

EUROLAB, with its state-of-the-art accredited laboratories and expert team, provides precise and fast testing services within the scope of TS 822 testing. This standard covers the description, classes, properties, sampling, inspection, tests and supply to the market of flat and corrugated sheets with a maximum thickness of 2,5 mm, galvanized by the hot-dip method.

This galvanizing method is the coating method applied before any action is taken on the product. Although it is a type of hot-dip galvanized coating, it differs in coating thickness and application sequence.

After the coil sheet is opened, it is continuously immersed in the molten zinc bath (450-460°C). After the excess zinc layer on it is smoothed, it is rolled up again and the manufacturer uses this sheet as its raw material. Coating Thickness is 15-20 µ. Materials made of pre-galvanized sheet metal with this coating thickness should be used mostly in areas with dry air such as inside the building and are recommended in areas where harmful substances and their indirect effects will cause corrosion.

EUROLAB assists manufacturers with TS 822 test compliance. Our test experts, with their professional working mission and principles, provide you, our manufacturers and suppliers, the best service and controlled testing process in our laboratories. Thanks to these services, businesses receive more effective, high-performance and quality testing services and provide safe, fast and uninterrupted service to their customers.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.