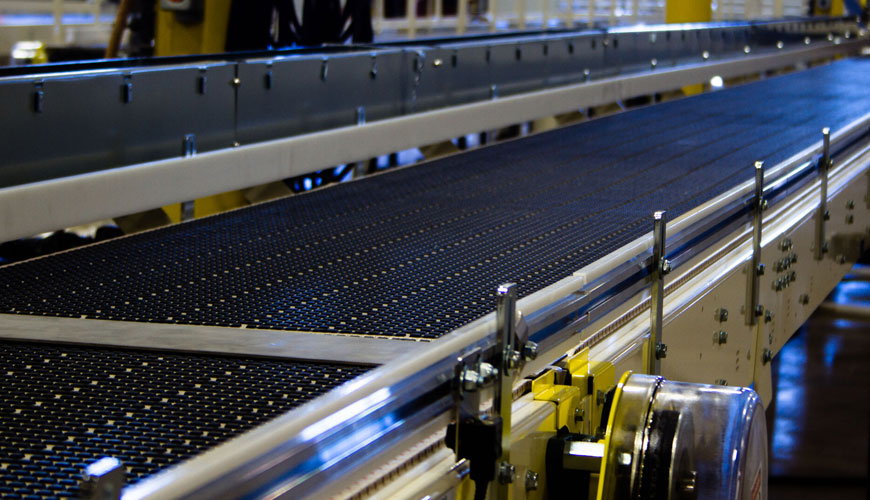

EUROLAB, with its state-of-the-art accredited laboratories and expert team, provides precise and fast testing services within the scope of EN 12881-1 testing. EN 12881-1 describes four methods for measuring flame propagation along a conveyor belt that has been exposed to a relatively highly localized heat source such as a fire. The damage suffered by the conveyor belt and its tendency to support combustion are measured by observing the extent to which the fire has spread throughout the test piece.

The purpose of the test methods described in EN 12881-1 is to provide an indication of the response of a conveyor belt to a fire situation. In doing so, however, attention has been drawn to the fact that in assessing the overall flammability properties of conveyor belts for particular installations, it is not sufficient to rely solely on any single test method, but each site location must also be considered.

The burners used in each method will be fed from bottled propane gas conforming to ISO 9162 and should be fed to each burner using a high pressure propane hose with a minimum inside diameter of 6,3 mm:

EUROLAB assists manufacturers with EN 12881-1 test compliance. Our test experts, with their professional working mission and principles, provide you, our manufacturers and suppliers, the best service and controlled testing process in our laboratories. Thanks to these services, businesses receive more effective, high-performance and quality testing services and provide safe, fast and uninterrupted service to their customers.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.