EUROLAB, with its state-of-the-art accredited laboratories and expert team, provides precise and fast testing services within the scope of EN 318 testing. This European standard specifies a method for determining dimensional changes in fibreboard due to climatic changes.

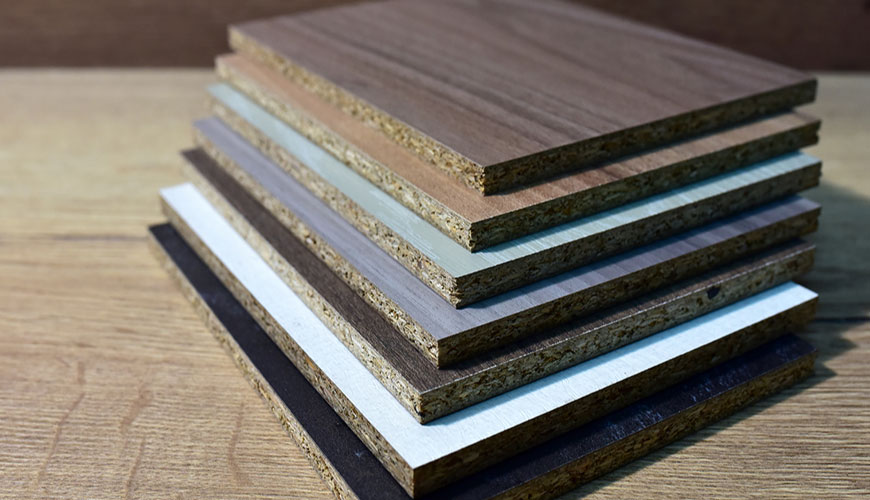

EN 318 is a European standard that specifies a method for determining dimensional changes associated with changes in relative humidity for fiberboards. This test method is important for evaluating the dimensional stability of fiberboards and their suitability for use in applications where they will be exposed to changes in humidity.

The test involves measuring the length and width of the fiberboard sample at a controlled relative humidity and then measuring the dimensions again after the sample is exposed to a different relative humidity. Dimensional changes are then calculated based on the size difference between the two conditions.

The standard specifies that test specimens should be rectangular in size and 50mm x 50mm x 5mm. Samples should be conditioned in a climate controlled environment for at least 24 hours prior to testing to ensure they are at a constant moisture content.

The test is typically performed using a conditioning chamber or cabinet that can control relative humidity. The first measurement is taken with the sample at a specific relative humidity, usually 65% or 50%, and the second measurement is taken after exposing the sample to a different relative humidity, typically 90% or 30%, for a period of time.

After the exposure time, the sample is removed from the chamber and allowed to equilibrate at room temperature for at least 1 hour before being measured. The length and width of the sample are measured at three points each using a digital micrometer and the average dimensions are calculated. Dimensional changes are then calculated as the percentage change in length or width between the two conditions.

The test method is useful for evaluating the dimensional stability of fiberboards under different humidity conditions and can be used to compare the performance of different types of fiberboards. The results can be used to determine whether fiberboards are suitable for use in applications where dimensional stability is important, such as flooring, furniture and cabinetry.

EUROLAB assists manufacturers with EN 318 test compliance. Our test experts, with their professional working mission and principles, provide you, our manufacturers and suppliers, the best service and controlled testing process in our laboratories. Thanks to these services, businesses receive more effective, high-performance and quality testing services and provide safe, fast and uninterrupted service to their customers.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.