EUROLAB, with its state-of-the-art accredited laboratories and expert team, provides precise and fast testing services within the scope of EN ISO 6721-7 testing. This standard describes a torsional, non-resonant method for determining the shear complex modulus G* components of solid polymers in the form of rods or rods at frequencies typically in the range of 0,001 Hz to 100 Hz. Higher frequency measurements can be made, but significant errors may occur in the measured dynamic properties.

The method is suitable for measuring dynamic storage modulus ranging from about 10 MPa, typical values obtained for hard rubbers, to about 10 GPa, representative of fiber-reinforced plastics. Although materials with modulus less than 10 MPa can be studied, more accurate measurements of their dynamic properties can be made using simple shear or torsional deformations of thin layers between parallel plates.

This method is particularly suitable for the measurement of loss factors greater than 0,02 and can therefore be conveniently used to study the variation of dynamic properties with temperature and frequency over most of the glass-rubber relaxation region. The availability of data determined over wide ranges of both frequency and temperature enables the derivation of master graphs using frequency-temperature shifting procedures that show dynamic properties over an extended frequency range at different temperatures.

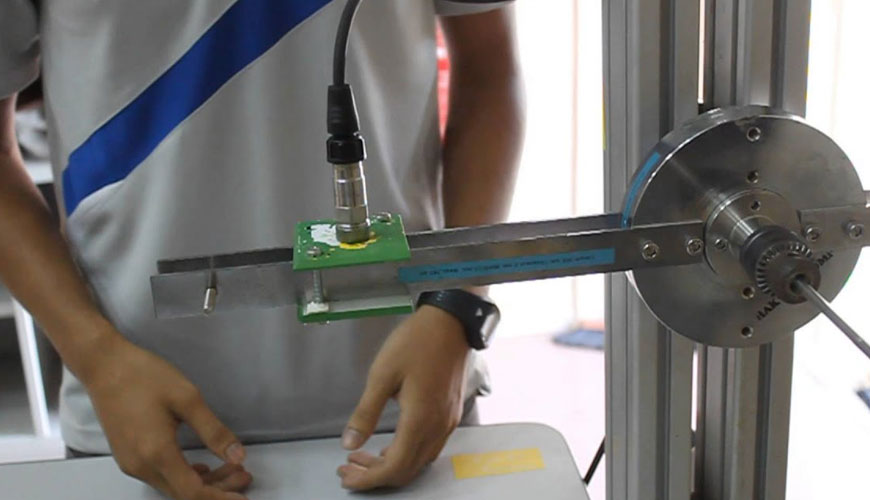

The sample is subjected to a sinusoidal torque or angular displacement at a frequency significantly below the fundamental torsional resonance frequency. The amplitudes of the torque and displacement cycles applied to the sample and the phase angle between these cycles are measured.

The clamps shall be able to grip the test specimen with sufficient force to prevent the specimen from slipping during torsional deformation and to maintain the force at low temperatures.

The distance between the two clamps should preferably be variable so that samples of different lengths can be accommodated and length corrections can be determined. A facility that allows for minor changes in clamp separation also allows for thermal expansion of the samples and is necessary to prevent defects in the modules that appear due to buckling of the samples at high temperatures.

EUROLAB assists manufacturers with EN ISO 6721-7 test compliance. Our test experts, with their professional working mission and principles, provide you, our manufacturers and suppliers, the best service and controlled testing process in our laboratories. Thanks to these services, businesses receive more effective, high-performance and quality testing services and provide safe, fast and uninterrupted service to their customers.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.