EUROLAB, with its state-of-the-art accredited laboratories and expert team, provides precise and fast testing services within the scope of ISO 1268-7 testing. This part of ISO 1268 specifies a method for preparing resin transfer molding (RTM) reinforced plastic test plates. It is intended to be read in conjunction with ISO 1268-1.

Resin transfer molding (RTM) is a low pressure manufacturing method performed in a closed mold. The fiber reinforcement can be preformed. The reinforcement is placed in the cavity of the mold and the mold is closed. The resin system is injected into the cavity to impregnate the reinforcement. The resin is then cured to form a composite plate. The procedure can be modified, for example, by applying a vacuum to remove air prior to resin injection, by heating the resin to reduce its viscosity and curing time, or by placing the resin and hardener separately when the resin is highly reactive.

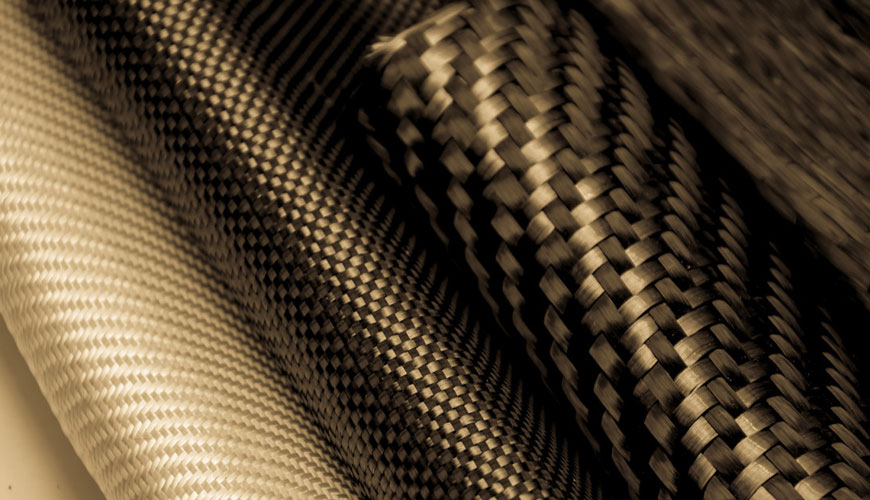

Glass, carbon, aramid, etc. Reinforcing fibers such as reinforcing fibers can be used in the form of mat (chopped strand or continuous strand felts), chopped rovings, woven fabrics, knitted fabrics, knits, unidirectional reinforcements, and combinations thereof.

The reinforcement can be preformed into a preform so that it retains its shape. Preforms can be produced by spraying binder onto the bonded reinforcement followed by thermosetting. Alternatively, ordinary reinforcements can be made into preforms by sewing, sewing or knitting together using auxiliary threads.

The reinforcement shall be such that it can be easily inserted into the mold cavity and impregnated with resin. Resin injection will not cause the reinforcement to move.

The length and width of the produced plate must be large enough to give the correct size test specimens for testing. The size of the test specimens shall be in accordance with the relevant International Standards. A length and width of 300 mm is recommended. The thickness will be between 1 mm and 4 mm. Thick plates are generally not suitable for use in the determination of mechanical properties.

EUROLAB assists manufacturers with ISO 1268-7 test compliance. Our test experts, with their professional working mission and principles, provide you, our manufacturers and suppliers, the best service and controlled testing process in our laboratories. Thanks to these services, businesses receive more effective, high-performance and quality testing services and provide safe, fast and uninterrupted service to their customers.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.