EUROLAB, with its state-of-the-art accredited laboratories and expert team, provides precise and fast testing services within the scope of ISO 1421 testing. ISO 1421 specifies two methods for determining the tensile strength of rubber or plastic coated fabrics.

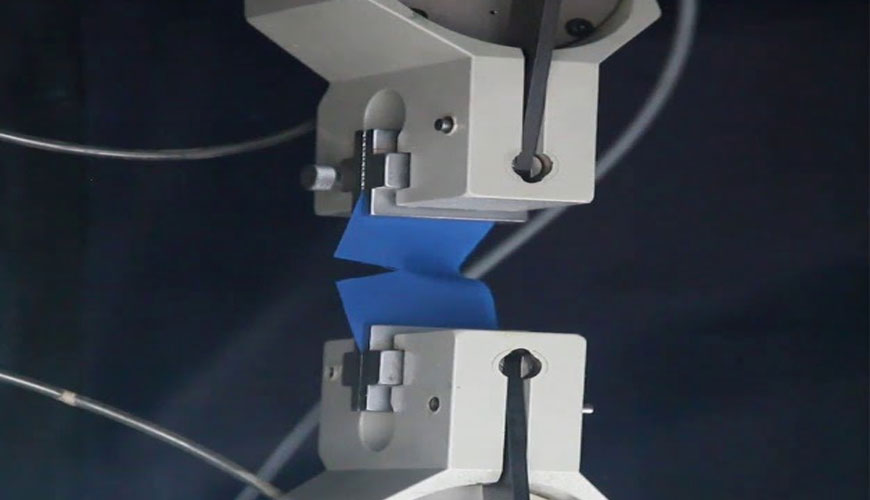

The methods are applied to test pieces and wet test pieces in equilibrium with specific standard atmospheres for testing. Both methods require the use of a constant elongation rate (CRE) tensile testing machine.

A test piece is extended at a constant rate of extension until it breaks. For method 1, the maximum force and elongation at maximum force and, if necessary, force at break and elongation at break are determined. For method 2, only the maximum force is determined.

For each of the five test pieces, record the maximum force and breaking force in both the longitudinal and transverse directions (this should be recorded to determine if it differs from the maximum force) and calculate the average value of the maximum force and the average value of the force at break in each direction. Round both the average maximum force and the average breaking force to the nearest 1 N or 1% of the calculated value. Calculate the coefficient of variation in each case and, if necessary, the confidence limits of the mean.

The machine must be equipped with means for reading and recording both the force applied to the test piece as it is stretched to the breaking point and the corresponding extension of the test piece. A strength gauge with several scales should be provided to ensure that the breakage of each test piece is achieved with a strength of between 15% and 85% of the maximum of the scale used. Under the conditions of use, the accuracy of the apparatus will be class 7500 as defined in ISO 1-1. The maximum force error specified or recorded at any point in the range in which the machine is used shall not exceed ± 1% and the specified or recorded jaw separation error shall not exceed 1 mm.

EUROLAB assists manufacturers with ISO 1421 test compliance. Our test experts, with their professional working mission and principles, provide you, our manufacturers and suppliers, the best service and controlled testing process in our laboratories. Thanks to these services, businesses receive more effective, high-performance and quality testing services and provide safe, fast and uninterrupted service to their customers.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.