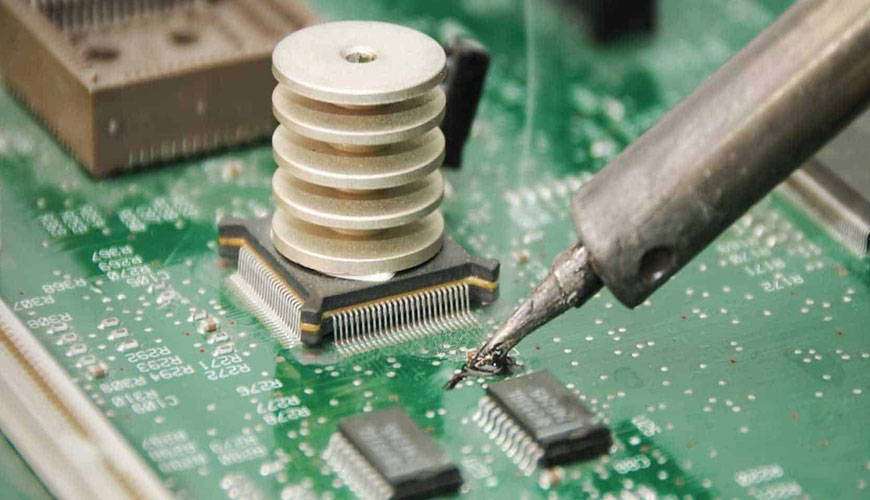

Temperature is an important element of safety, reliability and performance in printed circuit boards (PCBs). High temperatures can cause malfunctions and permanent damage in a short time. Certain conditions can cause heating during the operation of a printed circuit board. For example, a component mounted on the board may generate excessive heat. An external factor, for example another component in a complex system such as an aerospace system or medical application, can generate excess heat. Heat may build up on the card due to insufficient ventilation. Or, the heat generated during PCB assembly, drilling and soldering can cause excessive thermal stress on components and cause boards to fail.

Whatever the cause, it is necessary to manage heat to ensure that printed circuit boards can withstand the high thermal stresses they will inevitably encounter. At this point, there is a need for effective PCB heat dissipation techniques and ways to prevent PCB temperature rise.

Monitoring the temperature of printed circuit boards is critical because high temperatures can change the board's structure, degrade its performance, or cause it to fail.

The main types of damage caused by excessive heat in a printed circuit board are:

Before measuring temperature on printed circuit boards, it is important to identify the primary heat source on the board and locate the temperature sensors. Most of the heat generated on the PCB moves to the temperature sensor via ground pins connected to the bottom layer of the board. Because the pins are connected to the substrate, it has the lowest thermal resistance of any component of the board between the temperature sensor and the heat source.

PCB temperature measurement mainly includes three different steps:

Printed circuit boards are generally defined as high temperature printed circuit boards if they can withstand the temperature limit of 150 degrees. Some high-temperature printed circuit boards can withstand even higher temperatures, but boards made from materials with less heat resistance can only operate safely at much lower temperatures.

Among the numerous test, measurement, analysis and evaluation studies given to the enterprises by our organization, there are also tests for the resistance of the printed circuit board to the soldering heat.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.