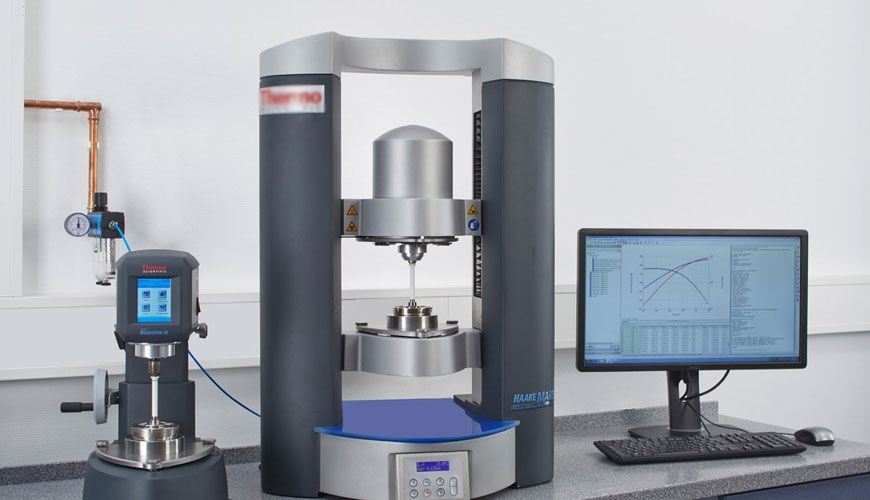

EUROLAB, with its state-of-the-art accredited laboratories and expert team, provides precise and fast testing services within the scope of EN ISO 6721-10 test. EN ISO 6721-10 specifies the general principles of a method for determining the dynamic rheological properties of polymer melts by means of an oscillation at angular frequencies, typically in the range of 0,01 rad s-1 to 100 rad s-1.

The method is used to determine the values of the following dynamic rheological properties: complex shear viscosity η *, dynamic shear viscosity η', out-of-phase component of complex shear viscosity η", complex shear modulus G*, shear loss modulus G" and shear storage modulus G'. It is suitable for measuring complex shear viscosity values, typically up to 10 MPa·s.

The angular frequency measuring range is limited by the characteristics of the measuring instrument as well as the response of the sample. When testing using angular frequencies less than 0,1 rad s-1, the test time can increase significantly, as the time taken to obtain a single measurement is proportional to the inverse of the angular frequency. As a result, sample degradation or polymerization is more likely to occur when testing at low angular frequencies and this has an impact on the results. At high angular frequencies, the specimen may bend or break at the edge, ultimately invalidating the test results.

The range of complex shear viscosity values that can be measured depends on the sample sizes as well as the characteristics of the measuring instrument. For a sample of certain sizes, the upper limit of the range is limited by the machine's torque capability, angular displacement resolution, and compatibility. However, adjustments can be made for cohesion effects.

The sample is subjected to either a sinusoidal torque or a sinusoidal angular displacement at a constant angular frequency. These are referred to as "controlled voltage" or "controlled voltage" test modes, respectively. When using the controlled voltage mode, the resulting displacement and the phase shift between torque and displacement are measured. When using the controlled strain mode, the resulting torque and the phase shift between displacement and torque are measured.

EUROLAB assists manufacturers with EN ISO 6721-10 test compliance. Our test experts, with their professional working mission and principles, provide you, our manufacturers and suppliers, the best service and controlled testing process in our laboratories. Thanks to these services, businesses receive more effective, high-performance and quality testing services and provide safe, fast and uninterrupted service to their customers.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.