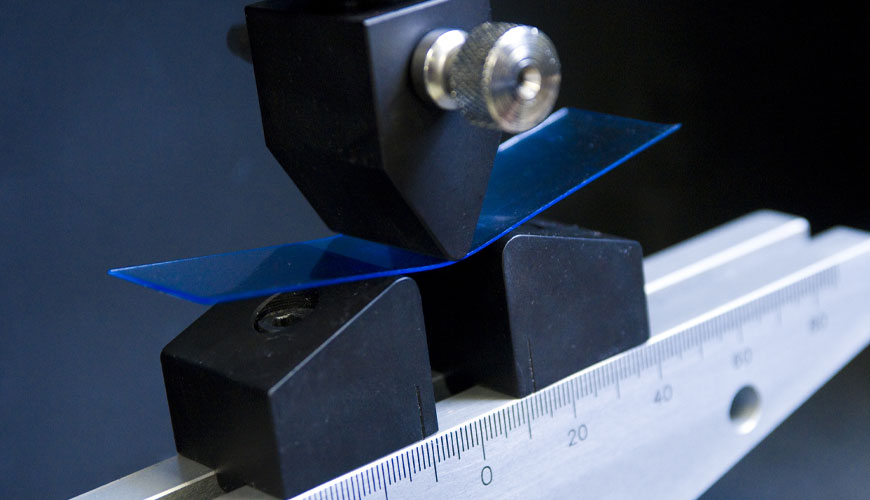

EUROLAB, with its state-of-the-art accredited laboratories and expert team, provides precise and fast testing services within the scope of ISO R527 testing. This IS0 Recommendation describes a method for determining the tensile properties of plastics in the form of standard test specimens tested under defined conditions of pretreatment, temperature, humidity, and separation rate of the jaws.

The test specimen to be used to test a particular material is as specified in the material specification. The first test sample will normally be found suitable for the materials, e.g. laminates with moderate elongations at break, based on thermosetting resins and many rigid thermoplastic molding materials; second for materials, eg. Three different test specimens are specified, namely polyethylene and plasticized polyvinyl chloride with relatively high elongations at break, and a third for thermosetting molding materials.

Different separation rates of the jaws are specified to suit the different materials to which the method can be applied. It is not possible to make a valid comparison between the results of tensile tests on different materials if the test specimens or the tensile rates or both are different.

Tensile properties that can be measured by some or all of the procedures described in this method include tensile stress and elongation at yield, tensile stress and elongation at break, maximum tensile stress, and modulus of elasticity.

Materials with low ductility may not show a well-defined yield point. Stress-strain curves at several different values of temperature, humidity, and strain rate generally give fairly reliable indications of the behavior of materials under tensile stress.

Tensile tests can provide data for quality control, acceptance or rejection in accordance with specifications, research and development, engineering design, and other purposes. Test results cannot be considered significant for applications where the stress application rate is significantly different from that specified for this test method. Such applications should be evaluated for tests such as impact, creep and fatigue.

EUROLAB assists manufacturers with ISO R527 test compliance. Our test experts, with their professional working mission and principles, provide you, our manufacturers and suppliers, the best service and controlled testing process in our laboratories. Thanks to these services, businesses receive more effective, high-performance and quality testing services and provide safe, fast and uninterrupted service to their customers.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.