The ratio of moisture sensitive active pharmaceutical ingredients (API) is quite high and the moisture barrier property of the packages of these drugs is of great importance. Water vapor transmission rate (WVTR) refers to the ability of water vapor to pass through solid material for a certain period of time.

All polymer materials used in pharmaceutical packaging are permeable to different degrees of gases and vapors. The main factors affecting the water vapor transmission rate of a package are the characteristics of the raw material as well as the wall thickness of the package. Medicine bottles made of high-density polyethylene (HDPE), polyethylene terephthalate (PET, PETE) or polypropylene (PP) materials have different water vapor permeability.

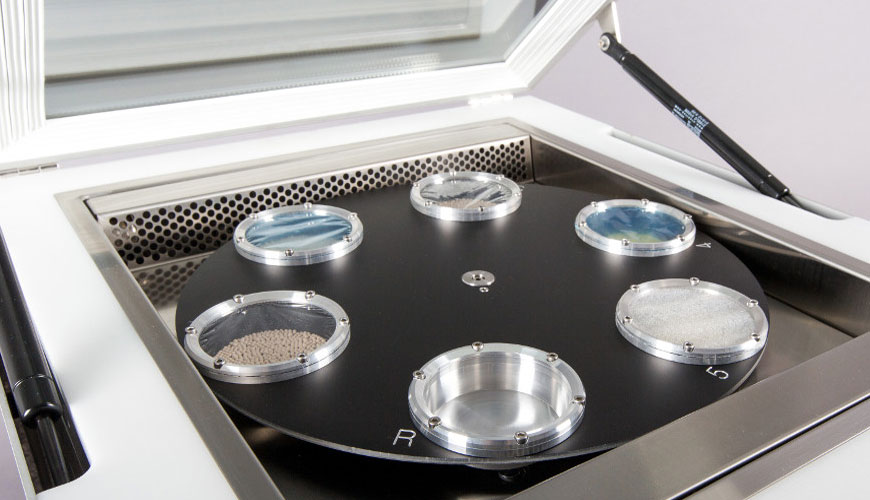

In advanced laboratories, medicine bottle closure systems are tested for water vapor transmission rate. In these tests, two main standards are followed in order to determine the permeability level of pharmaceutical container closure systems:

The ASTM D7709-12 standard, developed by the American Testing and Materials Association (ASTM), describes the following test methods for measuring water vapor transmission rates:

These containers are tested closed and sealed, and the test methods described are used for all primary containers and bulk primary containers of a size limited only by the dimensions and weighing capacity of the equipment and the precision of the balance. These tests are intended to have sufficient sensitivity and precision of containers to allow a distinction to be made between barrier levels of packages available for pharmaceutical products.

These test methods use the gravimetric measurement method to determine the rate of weight gain as a result of the delivery of water vapor to the package and subsequent uptake by a desiccant inside the package. Packages are generally exposed to a temperature of 40 degrees Celsius and a relative humidity of 75 percent.

The American Pharmacopoeia (USP) is an organization that defines quality standards for pharmaceuticals. The “USP <671> Barrier protection detection” standard published by this organization is basically based on the ASTM D7709-12 standard.

The stages of testing primary packaging according to the USP <671> standard include:

For companies working with pharmaceutical formulations or packaging that are sensitive to water vapor (moisture), barrier bottles that pass these tests provide the following values:

Meanwhile, water vapor transmission rate tests are carried out not only for the pharmaceutical industry, but also for flexible barrier materials used in various industrial applications. For example, in the “ASTM F1249-20 Standard test method for water vapor transmission rate from plastic film and coating using a modulated infrared sensor”, sheets consisting of single or multi-layer synthetic or natural polymers and foils, including coated materials, up to 3 mm thick and A test method applicable to films is described. In this test method, too, key factors are the thickness of the material and environmental factors such as relative humidity and temperature.

Our organization has a strong staff that closely follows the developments in the world in the field of science and technology and constantly improves itself. Water vapor transmission velocity (WVTR) testing services are among the numerous test, measurement, analysis and evaluation studies given to businesses.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.