Printed circuit boards, known as PCBs for short, are used to mechanically support and electrically connect electronic components using etched conductive paths and signal traces from copper sheets laminated onto a non-conductive substrate.

Today, printed wiring (circuit) boards are used almost everywhere except the simplest commercially produced electronic devices, allowing fully automated assembly processes that were not possible or practical in previous era label type circuit assembly processes.

A PCB filled with electronic components is called a printed circuit assembly, printed circuit board assembly, or PCB assembly. However, in general, the term PCB is used for both bare and assembled boards to explain the meaning.

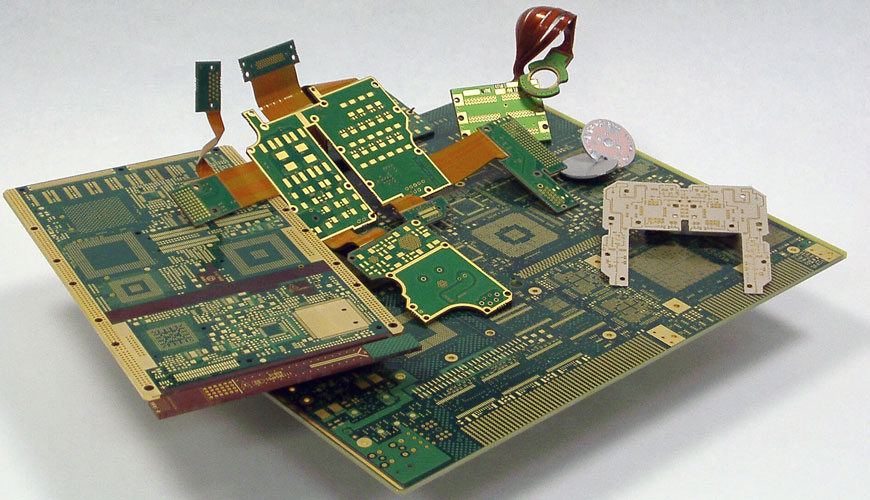

Printed circuit boards are circuit boards used in most electronic devices. These boards support the device both physically and mechanically as well as connecting electronic components. PCBs are typically made of materials with copper circuit layers. These layers can range from a single layer to a double layer and even fifty or more layers. There are several common types of PCB boards, each designed to offer the best quality for the product. For example, single-sided PCBs, double-sided PCBs, multilayer PCBs, rigid PCBs, flexible PCBs and rigid-flexible PCBs. These PCBs are found almost everywhere, in almost every electronic device used daily, such as microwave ovens, cell phones, computers and televisions.

Single-sided PCBs are made with just a layer of conductive material on one side of the board and the other side is used to combine different electronic components. Double-sided or double-layer PCBs have a thin layer of conductive metal applied to both sides of the board instead of one. Multilayer PCBs are circuit boards that usually have two or more layers. These layers are laminated to each other under high temperature and pressure to ensure that no air remains between the layers and that the special adhesive used to fix the boards to each other is properly melted and cured. Rigid PCBs are a form of circuit board that is rigid and inflexible and will not bend or flex due to the solid substrate material this board is made of. Flexible PCBs are made of material that can move or flex, unlike rigid PCBs, typically electronic devices are mounted on flexible plastic substrates. Rigid-flexible PCBs, on the other hand, are a hybrid circuit board that combines the features of both flexible and rigid boards, resulting in a form of board that can be folded or continuously bent.

Printed circuit board qualification tests cover a wide variety of printed circuit board testing methods that check whether a board meets relevant standards. Some of these standards are aimed at ensuring that the PCB functions properly according to the specifications of a project and is free of any defects. Power board testers and other circuit board testing methods are used to perform PCB tests.

Printed circuit board qualification testing procedures evaluate various components of PCBs. The primary components tested are:

Many of these factors are analyzed in early material testing and environmental testing. However, factors such as electrical conductivity and overall functionality are analyzed with various methods and equipment.

Our organization has a strong staff that closely follows the developments in the world in the field of science and technology and constantly improves itself. Among the numerous test, measurement, analysis and evaluation studies given to businesses, there are also printed circuit board proficiency testing services.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.